All American made

Parts

Inventing new sound

Vesper Cone & Spider

I have long observed the effect oxidation has on the tone and life of the heart of the resonator guitar: the cone. All cones degrade overtime because of the way aluminum interacts with oxygen in the air. The result is the surface of the cone becomes pitted and fuzzy with oxidation which kills the tonal qualities of the resonator system.

I am pleased to announce that after much time we are ready to release the Vesper™ Cone and Spider. By applying a micro-thin Ceramic Polymer to the surface of the aluminum, we are able to protect the cone from the oxidation process. As a result of creating a longer lasting cone, we also discovered new increased sonic attributes. The sustain of the legend cone, with a more pronounced high end.

Legend Cone™

The Legend Cone is the byproduct of a long tenure of trial and error, and an apprenticeship with the man who spun all the cones for Dobro from the 60s-90s. I had the pleasure to take the fundamentals I learned in my apprenticeship and create a new cone shape that is Triple Spun™ to create more sustain and response.

Biscuit 9.5

Synonymous for the classic blues sound, the early biscuit cone faced serious challenges in its early inception, primarily the molecular strength of the aluminum used. A lack of various aluminum alloys meant that in order to create a structurally sound cone, embossed spirals were added over the spun cone. This gave the cone increased strength but destroyed the tone and sustain of the cone. This generation of Beard resonators uses a high strength aluminum alloy that allows us to strictly spin the cone without any structural spirals. Ultimately, this gives us a more resonate and stronger cone.

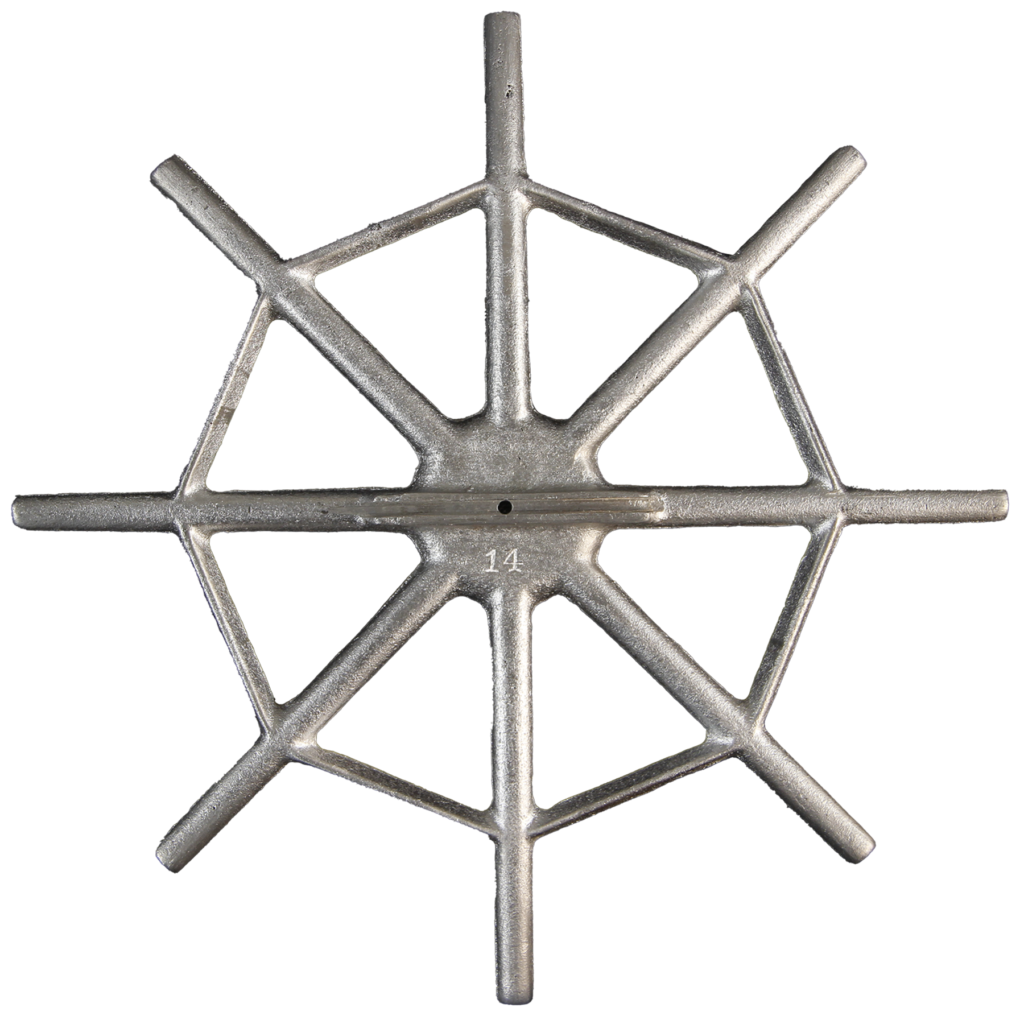

Original #14 Spider™

John Dopyera, creator of the Dobro/resonator guitar, created the first spider bridge system in the early 1930s. Whether by luck or design, he created the best sounding spider to be produced to this day. By chance, I discovered the original foundry that cast these spiders, and in the 90s, I learned they were going out of business. To my surprise, the foundry revealed that the Dobro company never owned the original 1930s pattern that was used for every #14 spider… the foundry did. As part of the liquidation sale of the foundry I was able to purchase the Original #14 spider pattern, the original mandolin spider pattern, and the original compensated spider pattern.

To carry on the tradition the Dobro company started, I continue to use these patterns for all of my spiders. Every spider is cast in the USA, and is arched, slotted, leveled, and cleaned in the Beard shop.